No products

Prices are tax excluded

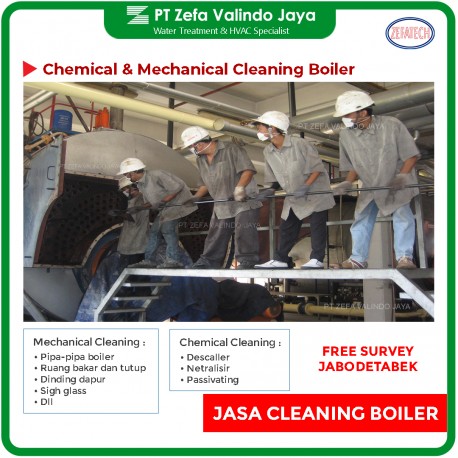

Boiler Cleaning Service - Chemical and Mechanical Cleaning

BoilerCleaning

New product

Form Survey : https://bit.ly/boiler-zefa

Free Survey untuk wilayah JABODETABEK.

More info

Boiler Cleaning Service (Chemical & Mechanical)

Boiler cleaning is the process of removing scale, deposits, and other contaminants from both the internal and external parts of a boiler system, which can affect the system's performance. This process is essential to maintain the efficiency, safety, and lifespan of the boiler. Boiler cleaning can be performed using either mechanical or chemical methods, depending on the type and severity of the fouling.

We offer a comprehensive boiler cleaning service, using a combination of chemical and mechanical cleaning methods, conducted by skilled technicians and supported with special chemicals that are effective and safe for boiler systems.

CHEMICAL CLEANING

-

Descaling Process: Involves circulating Aquaright D200Solvent to dissolve carbonate scale, and Aquaright SC100R to remove silica and phosphate scale.

-

Neutralization Process: Uses Aquaright A055 (pH adjuster) to balance the pH and alkalinity of boiler water after the cleaning process.

-

Passivation Process: Circulates Aquaright PP205 to prevent future scaling by converting hardness salts into sludge particles that can be removed through blowdown, thus avoiding scale formation.

MECHANICAL CLEANING

-

Tube descaling using mechanical rod or brush

-

Cleaning of combustion chamber cover

-

Internal combustion chamber cleaning

-

Cleaning of furnace wall with diesel

-

Fire-tube cleaning with compressed air

-

Sight glass cleaning

-

And more as needed

BENEFITS OF BOILER CLEANING

-

Improves Efficiency: Scale and deposits reduce heat transfer, requiring more energy to reach target temperatures.

-

Prevents Damage: Accumulated deposits can cause corrosion and damage components such as tubes and pumps.

-

Ensures Safety: A dirty boiler poses a higher risk of fire and other safety hazards.

-

Improves Steam/Hot Water Quality: Contaminants can negatively affect the quality of steam or water used in production processes.

-

Extends Boiler Lifespan: Regular cleaning helps maintain optimal performance and prolongs equipment life.

-

Regulatory Compliance: Routine maintenance supports adherence to industrial safety and operational regulations.

REQUIRED DATA

To prepare a proper quote and planning, please provide:

-

Company Name

-

PIC Name and Contact

-

Boiler Manufacturer

-

Design Type

-

Model Number

-

Number of Units

-

Evaporation Capacity [Max (Ton/Hour) and Operating (Ton/Hour)]

-

Pressure [Max (Kg/cm²) and Operating (Kg/cm²)]

-

Operation [Hours/Day and Days/Month]

-

Condensate Return (%)

-

Feedwater Temperature (°C)

-

Type of Pre-treatment Plant

-

Blowdown Equipment

-

Monthly Make-Up Water Volume

-

Additional Information (if any)

Survey Form: https://bit.ly/boiler-zefa

Free Survey available for JABODETABEK area

We also provide Cleaning Services for Cooling Towers, and Water & Wastewater Treatment Solutions.