-

1 x AQUARIGHT...RP . 64,200.00

1 x AQUARIGHT...RP . 64,200.00

No products

Prices are tax excluded

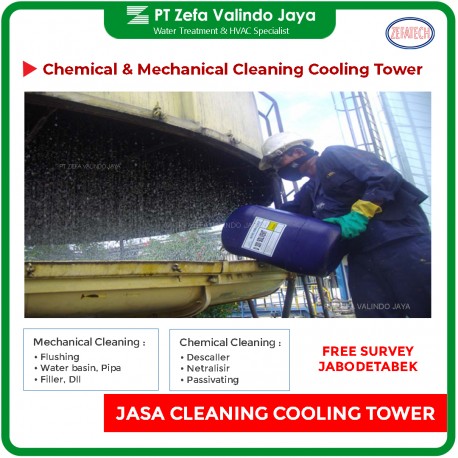

Jasa Cleaning Cooling Tower - Kimia dan Mekanikal

CoolingCleaning

New product

Form Survey : https://bit.ly/cooling-zefa

Free Survey untuk wilayah JABODETABEK.

More info

WHAT IS A COOLING WATER SYSTEM?

A Cooling Water System or Cooling Tower is a system used to remove heat from water that has been used in industrial processes or cooling systems (such as HVAC), by lowering the water temperature through evaporation or heat exchange processes.

Hot water from production processes is channeled to the cooling tower and cooled either through direct contact with air or through heat exchange media, before being recirculated back into the system. Cooling towers are essential for maintaining system efficiency and preventing overheating in industrial equipment or commercial buildings.

COMMON ISSUES IN COOLING WATER SYSTEMS

-

Corrosion

-

Scaling

-

Suspended Solid Sludge

-

Biofouling (slime, algae, bacteria, microorganisms)

CHEMICAL CLEANING IN COOLING WATER SYSTEMS

- Descaling Process

Uses Aquaright D200 Solvent to dissolve carbonate scale and Aquaright SC100R to dissolve silicate and phosphate scale. - Neutralization Process

Uses pH adjuster Aquaright A055 to regulate pH and alkalinity in the boiler water after washing or cleaning the cooling tower. - Passivating Process

Uses Aquaright PP205 to prevent scale formation.

MECHANICAL CLEANING IN COOLING WATER SYSTEMS

-

System water flushing and draining

-

Cleaning deposits and scale in the basin and piping

-

Spraying and scraping inside the tower

-

Inspection and cleaning of nozzles, filler media, and drift eliminators

-

Inspection of metal components for corrosion

-

And more

BENEFITS OF CLEANING COOLING WATER SYSTEMS

-

Improves heat transfer efficiency

-

Saves energy and operational costs

-

Reduces risk of damage and system downtime

-

Extends equipment lifespan

-

Maintains water and air quality in HVAC systems

-

Meets environmental and occupational safety standards

CHEMICALS FOR COOLING WATER SYSTEM MAINTENANCE

Aquaright CH 10 N

A corrosion and scale inhibitor for closed cooling systems and chilled water circuits using distilled water, soft water (Total Hardness < 50 mg/L as CaCO₃), or freshwater.

Aquaright CTS 505

A blend of organophosphorus compounds, selected polymers, and dispersants, designed to control corrosion and prevent scale formation in large circulating open cooling systems using moderately hard to hard make-up water.

Aquaright CB 303

A broad-spectrum biocide containing Isothiazolone, effective at very low concentrations for controlling planktonic and surface growth of bacteria, fungi, and algae in cooling water systems.

Aquaright B-TAB

An organic water-soluble, non-volatile, non-foaming biocide tablet, specifically formulated to control slime-forming bacteria and other biological growth in air conditioning condensate pans. A fast-acting broad-spectrum biocide that keeps condensate pans clean and ensures smooth drainage.

CORROSION IN COOLING WATER SYSTEMS

Factors affecting corrosion rates in cooling systems include:

- pH

Most metal oxides are soluble in acidic media, increasing corrosion at low pH. - Dissolved Salts/Minerals

Chloride (Cl) and sulfate (SO₄) ions can penetrate metal protective layers and accelerate corrosion. - Dissolved Gases

Common dissolved gases include CO₂ (lowers pH), O₂ (accelerates corrosion), NH₃ (forms corrosive complexes with copper), H₂S (acidic and lowers pH), and Cl₂ (damages protective film and reduces pH). - Suspended Solids

Particles like mud, sand, and dust settle in low-flow areas, causing local aeration differences that lead to localized corrosion. - Microorganisms

Certain bacteria produce corrosive acids, e.g., Desulfovibrio (produces H₂S), Thiobacillus (produces H₂SO₄). Anaerobic bacteria reduce surface aeration and promote corrosion. - Metal Surface Composition

Metals with high reactivity (e.g., Fe, Al, Mg) corrode faster, especially in high-conductivity water. - Temperature

Higher temperatures increase corrosion. In closed systems, corrosion rates rise with temperature due to oxygen entrapment. - Water Flow Velocity

Faster water flow typically increases corrosion by thinning protective films and speeding up oxygen penetration. - Metal Issues

Scratches, cracks, stress, or uneven purity accelerate corrosion cell formation.

CORROSION PREVENTION IN COOLING WATER SYSTEMS

Passivation

Uses inhibitors (e.g., chromate, nitrite, molybdate, phosphonates) to create a protective oxide film on metal surfaces.

Precipitation

Uses zinc and hydroxide ions to form protective precipitate films.

Adsorption

Uses amines and tannins to absorb onto metal surfaces and stabilize them.

Removal

Corrosive elements are removed depending on cause, e.g., oxygen (with sodium sulfite), low pH (adjusted with lime).

CORROSION INHIBITOR CHEMICALS FOR COOLING WATER SYSTEMS

Inhibitors include zinc salts, phosphonates, HEDP, ATMP, triazole, molybdate, and nitrite.

PT Zefa Valindo Jaya, with over 25 years of experience in water treatment and specialty chemicals, offers high-performance corrosion inhibitors, including:

Aquaright CTS 505

A concentrated blend of organophosphorus compounds, selected polymers, and dispersants. Key benefits: fully organic with minimal environmental impact, strong threshold dispersants, high concentration (low dosage, low storage cost), and resistant to degradation by oxidizing biocides.

Aquaright CH 10 N

A liquid inhibitor for closed cooling and chilled water systems using distilled or soft water. Effective even if oxygen reenters the recirculating water. Suitable for most metals including copper and aluminum. Typically used with an effective biocide (unless used with freshwater generators for drinking/cooking).

SCALING IN COOLING WATER SYSTEMS

Scale forms when dissolved mineral salts in water exceed their solubility limits and begin to crystallize. Common types include:

-

Calcium carbonate (CaCO₃)

-

Calcium phosphate (Ca₃(PO₄)₂)

-

Calcium sulfate (CaSO₄)

-

Silica (SiO₂)

Scale Formation Process : Precipitation → Coagulation → Consolidation → Compression (Crystal/Scale)

Problems Caused by Scale:

-

Impairs heat transfer in H/E, condensers, evaporators/chillers

-

Causes temperature and pressure fluctuations

-

Leads to unexpected equipment failure

-

Triggers corrosion under the scale layer

-

Decreases system efficiency

-

Increases maintenance costs

Factors that influence scale formation:

-

High temperatures

-

pH and alkalinity conditions

-

Mineral concentration

-

Microorganisms (e.g., Gallionella)

-

Evaporation load factor

-

Overdosing water treatment chemicals like phosphate

SCALE PREVENTION IN COOLING WATER SYSTEMS

Three key principles:

-

Careful control of pH and alkalinity

-

Bleed-off practices to maintain mineral levels below saturation limits

-

Use of chemical additives to inhibit scaling even with high mineral content

The most effective program combines all three methods comprehensively.

SCALE CONTROL IN COOLING WATER SYSTEMS

1. Using Ion Exchange

Ion exchange is a type of Water Treatment Plant where ions in a compound are exchanged—cations for cations, and anions for anions. Common processes include Softener, Demineralization, and Mixed Bed.

-

Softener

A softener system removes calcium and magnesium ions (hardness) from water. Its main purpose is to reduce water hardness, which can lead to scale formation. -

Demineralization

Demineralization is a water purification system that reduces or eliminates mineral content in water by absorbing mineral ions into resin and replacing them with other ions from the resin.

2. Using pH Adjustment : Acid Dosing (H₃PO₄, H₂SO₄, or HCl)

3. Using Chemical Additives : Polyphosphates, Phosphonates, HEDP, ATMP, and Triazole Derivatives.

CHEMICALS FOR SCALE PREVENTION IN COOLING WATER SYSTEMS

Several scale inhibitors for cooling water systems include phosphonates, maleic acid homopolymers, triazole derivatives, hydroxyethylidene-1,1-diphosphonic acid (HEDP), methylene phosphonic acid, acrylic acid-based terpolymers, and maleic acid-based copolymers.

One specially formulated chemical product by PT Zefa Valindo Jaya for scale prevention in cooling water systems is Aquaright CTS 505.

Aquaright CTS 505 is a blend of organophosphorus compounds, selected polymers, and dispersants, designed to prevent scale deposition and control corrosion in large recirculating open cooling systems operating with medium to hard make-up water.

SUSPENDED SOLIDS (SLUDGE) IN COOLING WATER SYSTEMS

Suspended solids are particles or colloids in water, either organic or inorganic.

Types of Suspended Solids:

-

Particles from the surrounding environment (Ecological Pollution)

-

Corrosion products

-

Loosened scale or debris

-

Dead microorganisms/algae (Dead Biomass)

Factors Influencing Suspended Solids Formation:

-

Cooling Tower Location

Avoid placement near pollution sources such as smoke, dust, leaves, or waste. -

Treatment Type

Select an appropriate treatment program based on water characteristics. -

Contaminants in Water

Sources like surface water or wastewater. -

Dead Algae/Microorganisms

Uncontrolled algae growth in the cooling system.

Problems Caused by Suspended Solids:

-

Blockages

-

Abrasion

-

Waste of treatment chemicals absorbed by solids

-

Increased equipment maintenance costs

CHEMICALS FOR TREATING SUSPENDED SOLIDS IN COOLING WATER SYSTEMS

-

Dispersion of Particles

Using Aquaright P311, a polymer that helps clean scale and sludge in chillers and cooling systems. It disperses, softens, and smoothens deposit particles. -

Coagulation

Using inorganic coagulant Aquaright KP35AC, which clarifies water by aggregating fine particles into larger clumps for settling or removal. -

Flocculation

Adding long-chain anionic or cationic polymers. Anionic flocculant: Aquaright A6025, binds small particles for rapid settling. Cationic flocculant: Aquaright C6660, binds sludge for easier separation. -

Separation or Clarification through Sedimentation and Filtration

BIOFOULING IN COOLING WATER SYSTEMS

Algae, bacteria, protozoa, and other microorganisms can form colonies known as biofouling, which thrive in cooling towers/systems.

Algae can damage wooden TowerPack/Splash Packs via rapid delignification. In plastic fillers, algae growth reduces evaporation surfaces and may cause filler collapse due to excess weight.

Slime produced by biofouling reduces heat transfer efficiency in heat exchangers. The heat resistance of slime is five times greater than scale.

Common areas of slime and sludge accumulation:

-

HE condenser chiller evaporator (tubes and shell)

-

Cooling towers (spray boards, tower packing)

-

Cooling tower basin (floor and walls)

Issues caused by slime and sludge:

-

Reduced heat exchanger efficiency

-

Clogging of heat exchangers

-

Increased pump pressure and reduced water flow

-

Reduced cooling tower efficiency

-

Accelerated corrosion

-

Damage to tower packing

-

Increased chemical consumption

-

Dirty appearance

FACTORS AFFECTING SLIME (BIOFOULING) FORMATION

-

Nutrients – Carbon, Nitrogen, and Phosphorus are abundant in water.

-

Energy sources – Sunlight, organic/inorganic matter.

-

Water Temperature – Optimal for microorganisms: 30–45°C.

-

pH Level – Bacterial growth: pH 6–9 (ideal for corrosion/scale control: pH 6.5–9); Fungi: pH 5.5–6.5.

-

Dissolved Oxygen (DO) – Aerobic bacteria and fungi thrive in oxygenated water.

Microorganisms producing slime:

-

Algae (Green-blue, blue, diatoms) – Chlorophyll-containing, sunlight-dependent. Common in open systems.

-

Bacteria:

-

Zoogloeal sp: Gelatinous colonies in organic-rich water.

-

Sphaerotilus sp: Cotton-like colonies in organic-contaminated water.

-

Iron bacteria: Convert ferrous to ferric iron, which precipitates.

-

Sulfur bacteria: Found in dirty water, oxidize H₂S (e.g., Thiobacillus).

-

Nitrifying bacteria: Oxidize NH₃ to HNO₂ and HNO₃.

-

Sulfate-reducing bacteria: Anaerobically reduce sulfate to H₂S.

-

-

Fungi:

-

Phycomycetes and Mycomycetes: Spore-developing mycelium-based algae-like fungi.

-

BIOFOULING PREVENTION IN COOLING WATER SYSTEMS

All types of biocides can effectively prevent biofouling, but each type has unique characteristics suitable for specific organisms.

For bacterial issues, PT Zefa Valindo Jaya offers Aquaright CB303, a broad-spectrum biocide with Isothiazolone, effective at very low concentrations for controlling planktonic and surface bacteria, fungi, and algae in cooling water systems.

For general microorganisms, chlorine tablets or Aquaright B-TAB (organic biocide tablets) can be used. These water-soluble, non-volatile, and non-foaming tablets are specially formulated to inhibit slime-forming bacteria and other biological growth in AC condensate drain pans. They act quickly to keep drain pans clean and ensure smooth water drainage.