What Particle Sizes Can a HEPA Filter Capture?

What is HEPA Filter?

High Efficiency Particulate Air (HEPA) filter is a type of air filter with a high efficiency standard designed to capture fine particles in the air, including those invisible to the human eye. HEPA filters are highly effective in various applications that require clean air, such as hospitals, laboratories, pharmaceutical industries, commercial buildings, and everyday use in both offices and homes.

What Particle Sizes Can a HEPA Filter Capture?

A HEPA filter is a type of filter that meets specific standards for capturing small airborne particles. To meet HEPA criteria, a filter must be capable of capturing at least 99.97% of particles that are 0.3 microns (μm) or larger. The 0.3-micron size is considered the "most penetrating particle size" (MPPS), meaning these particles are the hardest to filter. If a filter can efficiently capture 0.3-micron particles, it is also capable of capturing both larger and smaller particles with high efficiency.

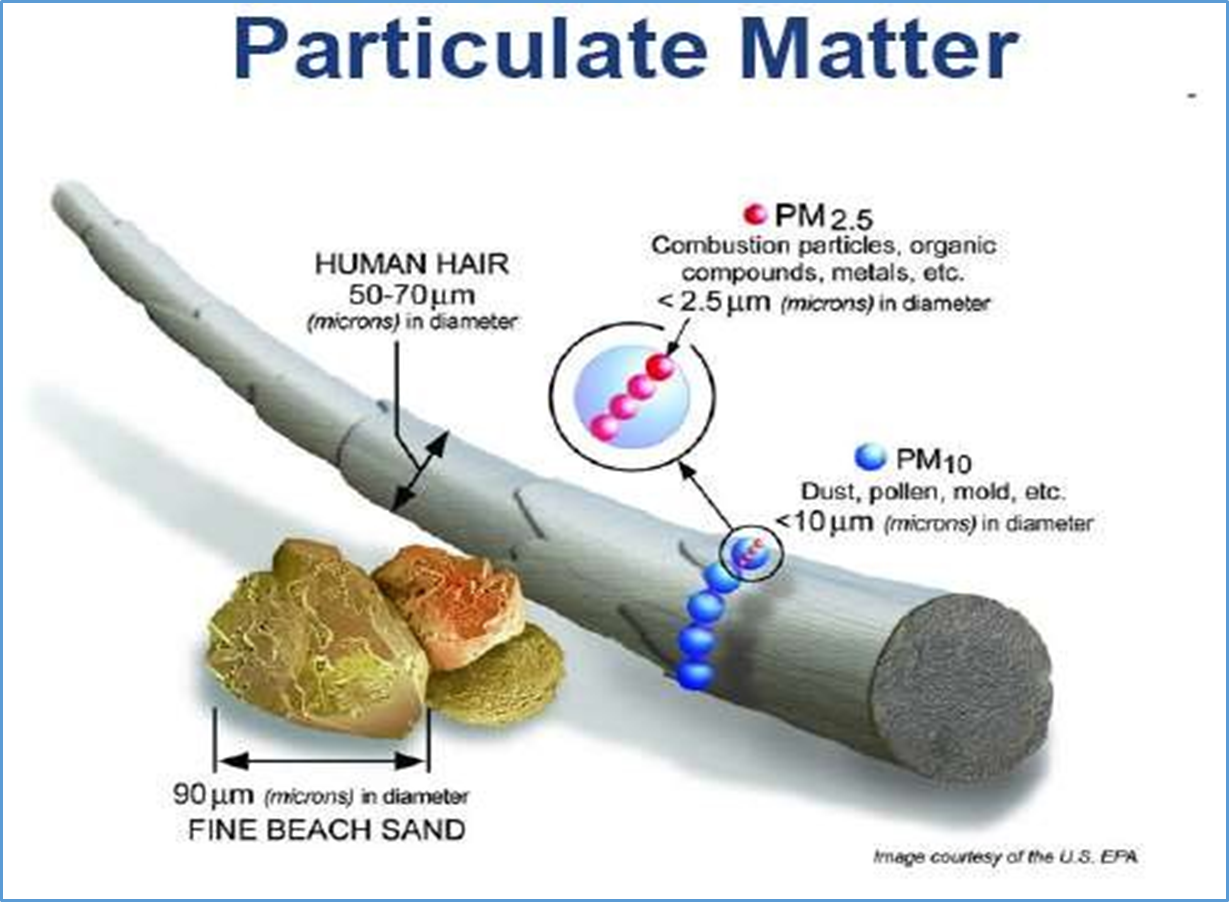

- A human hair is approximately 50–70 microns in diameter.

- Dust particles are typically smaller than 10 microns.

- Sand grains range from 90–1000 microns in size, much larger than dust particles and generally do not remain airborne for long, unless in windy areas.

- Pollen particles are smaller than 10 microns and are a common cause of allergies.

- Dust particles smaller than 2.5 microns are very fine and can penetrate deep into the respiratory system.

- Bacteria typically range from 0.3 to 10 microns.

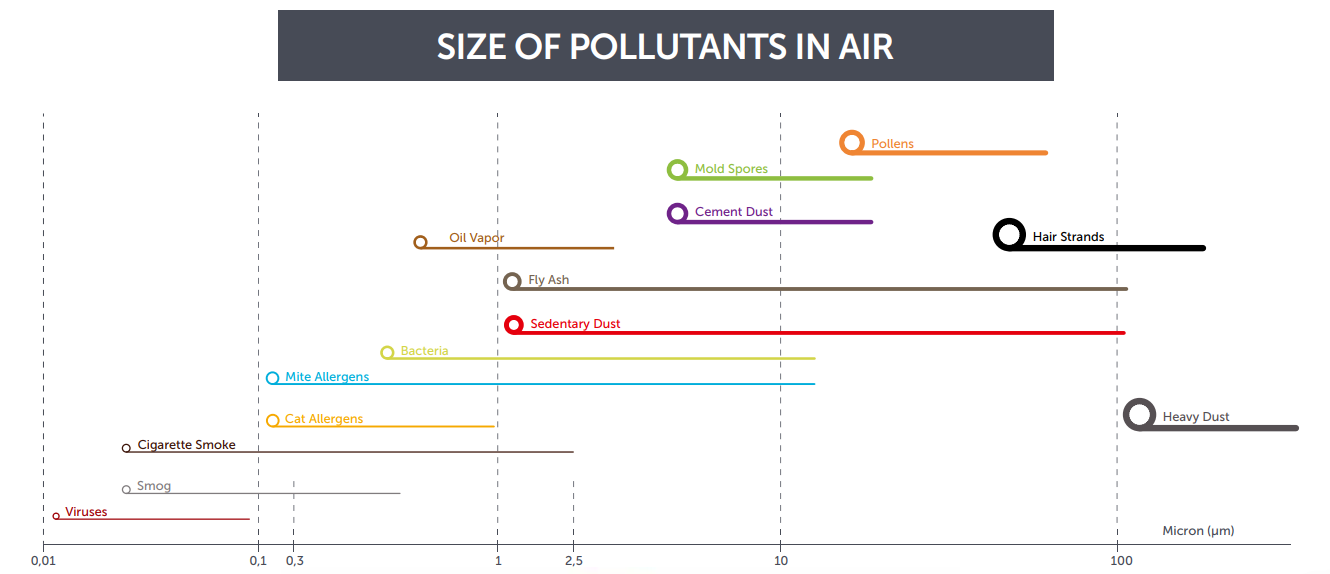

- Viruses range from 0.005 to 0.3 microns. Viruses are much smaller than bacteria. Some viruses may be too small to be captured by a HEPA filter but can become trapped if they adhere to larger particles or aerosols.

- Cigarette smoke particles range from 0.01 to 1 micron. Smoke contains various types of very fine particles that are often difficult to filter completely. To address this, activated carbon filters are often used in conjunction with HEPA filters in air filtration systems. Activated carbon filters are highly effective in adsorbing and trapping gas molecules and odors, including volatile organic compounds (VOCs) present in cigarette smoke.

.png)

Why and Where Should HEPA Filters Be Used?

-

Hospitals and Healthcare Facilities:

In medical environments, the use of HEPA filters is not just optional but essential to prevent contamination and infection. By filtering out bacteria and viruses from the air, HEPA filters help protect vulnerable patients, such as those recovering from surgery or with weakened immune systems. HEPA filters are commonly installed in operating rooms, isolation rooms, laboratories, and emergency departments. -

Food and Beverage Factories:

In the food and beverage industry, air contamination can affect product quality and safety. HEPA filters help maintain sterile air, reducing the risk of contamination from dust, mold spores, and microorganisms. They are used in production areas, packaging rooms, and food storage spaces. -

Pharmaceutical Industry:

Pharmaceutical products are highly sensitive to contamination. HEPA filters help ensure product quality by keeping the air free of harmful particles and microorganisms that could affect the purity of medicines. HEPA filters are used in research laboratories, production rooms, and pharmaceutical storage areas. -

Office Buildings and Malls:

Commercial buildings such as offices and shopping malls have closed air circulation systems and are at risk of spreading airborne pathogens. HEPA filters help reduce indoor air pollution, which can come from external pollutants or indoor activities. In office buildings and malls, HEPA filters are often integrated into HVAC systems. -

Other Enclosed Spaces:

HEPA filters can also be used in other enclosed spaces frequently used for everyday activities, such as offices and homes. Typically, HEPA filters are used in portable units, often referred to as air purifiers.

HEPA Filter Standards and Certifications

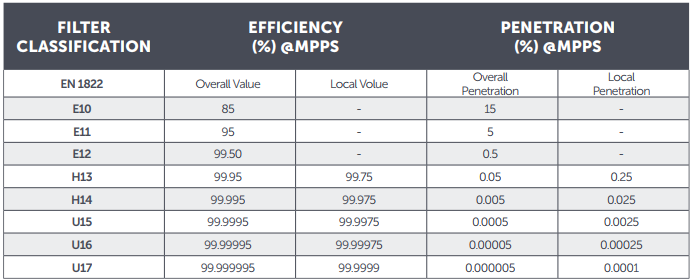

One of the main HEPA filter standards is EN 1822, the European standard used to classify and test the efficiency of high and very high-efficiency air filters (EPA, HEPA, and ULPA). EN 1822 defines the testing method for air filter efficiency by calculating the particles using test aerosols entering the clean side at a specific airflow velocity. The EN 1822 classification is based on the measurement of the MPPS (Most Penetrating Particle Size), which is the particle size that is most difficult for air filters to capture.

HEPA filters play a crucial role in preventing the spread of pollutants, allergens, and pathogens in the air. Their use is not limited to healthcare facilities like hospitals but extends to the food, pharmaceutical industries, commercial buildings, offices, and homes. Choose and acquire the appropriate HEPA filter products for your needs. For more information, contact us at +62 21 8873 531 or email us at info@zevanya.com.